Why Do Many Luxury Cars Give up All-aluminum Bodies?

The all-aluminum body is a term that has been mentioned for many years in the automotive market, and many car companies even use the all-aluminum body as a selling point, which is one of the marketing methods to highlight the sense of luxury and increase the sale. The question is, is an all-aluminum body really that good?

The all-aluminum body doesn't mean that the whole car body is made of aluminum. We can't find a mass-produced car made of pure aluminum now. The all-aluminum body is actually a car body with aluminum main frames and covering parts. Materials used for the car body are aluminum and other metal elements. Car companies will calculate the proportion of various metal elements according to the different structures of the body to obtain a sufficiently coordinated frame.

The density of aluminum alloy is only one third of that of steel, so aluminum alloy is lighter than steel. First, car bodies adopting all aluminum will have more advantages in terms of curb weight, which have less economical energy consumption and better dynamic performance. Second, car bodies made of all aluminum have better plasticity, that is, being soft enough. The car body has more shapes, which enables the design to obtain the sense of beauty and makes the product have better appearance. Third, car bodies using all aluminum have good corrosion resistance. Aluminum alloy has better stability than steel in the long term.

Car companies have always highly praised the all-aluminum body in the early stage, especially the luxury brands that have used it as a symbol. For example, Audi was one of the early companies that used all-aluminum bodies. All-aluminum bodies can be seen for sports cars R8 and TT, which caused a certain sensation on the car market at that time. However, why doesn't Audi seem to blindly pursue the selling point of the all-aluminum body?

After a new technology is developed for a company, try to use it for all the products as much as possible. Otherwise, it is not very convincing if only a car costing millions is taken as an example in publicity. Aluminum alloy is very expensive and can only be applied to high-end products with relatively high profits. If it is used for all cars, there won't be any profit. Therefore, it's difficult to apply aluminum alloy to all cars. Also, there is difficulty in welding and repairing the all-aluminum body, especially after a collision. It is even cheaper to buy a new one than to repair it.

When the all-aluminum body was just launched, car companies used its safety performance as a selling point. However, after many traffic accidents, the result was not as simple as it was thought. It is undeniable that the strength of aluminum alloy is not low, but it is too easy to deform. Once there is external force, aluminum alloy will have a round shape. With the development of technology, hot-formed steel has better strength than aluminum alloy. Some top high-impact steels have a strength of 1800Mpa, and their density is much lower than ordinary steel, which can meet the requirements of weight reduction and safety. More importantly, the cost of a high-impact steel body is much lower than that of an all-aluminum body.

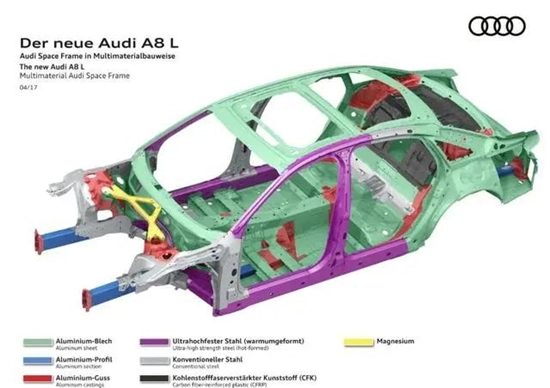

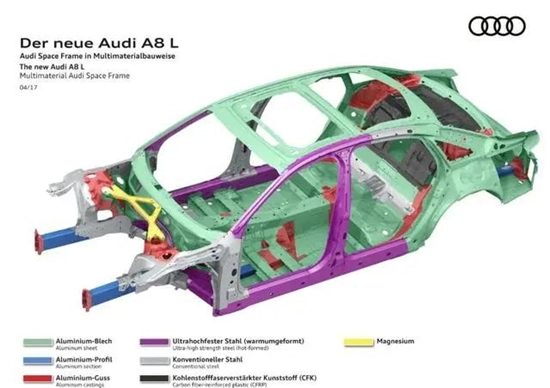

Of course, we can not equal the high-impact steel with aluminum alloy in terms of light weights. Therefore, high-impact steel will be used for the area requiring high-impact energy absorption, such as A-pillars and B-pillars, while aluminum alloy is used for the easily crushed area after weighing by car companies. By doing this, both safety and light weights can be taken into account.

Generally speaking, the advantages and disadvantages of the all-aluminum body are very obvious. It has an irreplaceable performance for the lightweight and handling performance of the vehicle, but the disadvantages are also fatal. In an era when people are increasingly concerned about car safety, the aluminum alloy body with high prices can not meet the existing safety standards; coupled with the shortcomings of difficult maintenance and high costs, the aluminum body is gradually not welcomed by the car market.

However, the new energy market has emerged, and the all-aluminum body has become a hot topic again in recent years. Because the curb weight of electric vehicles is much heavier than that of traditional fuel vehicles, aluminum alloys have become the first choice in order to reduce weights and increase continuation of the journey. For example, the NIO ES8 uses an all-aluminum body. Judging from the ES8's recent five-star evaluation in the E-NCAP crash test, it seems that with the iteration of technology, the safety performance of the all-aluminum body may also be overcome in the future.

The all-aluminum body doesn't mean that the whole car body is made of aluminum. We can't find a mass-produced car made of pure aluminum now. The all-aluminum body is actually a car body with aluminum main frames and covering parts. Materials used for the car body are aluminum and other metal elements. Car companies will calculate the proportion of various metal elements according to the different structures of the body to obtain a sufficiently coordinated frame.

The density of aluminum alloy is only one third of that of steel, so aluminum alloy is lighter than steel. First, car bodies adopting all aluminum will have more advantages in terms of curb weight, which have less economical energy consumption and better dynamic performance. Second, car bodies made of all aluminum have better plasticity, that is, being soft enough. The car body has more shapes, which enables the design to obtain the sense of beauty and makes the product have better appearance. Third, car bodies using all aluminum have good corrosion resistance. Aluminum alloy has better stability than steel in the long term.

Car companies have always highly praised the all-aluminum body in the early stage, especially the luxury brands that have used it as a symbol. For example, Audi was one of the early companies that used all-aluminum bodies. All-aluminum bodies can be seen for sports cars R8 and TT, which caused a certain sensation on the car market at that time. However, why doesn't Audi seem to blindly pursue the selling point of the all-aluminum body?

After a new technology is developed for a company, try to use it for all the products as much as possible. Otherwise, it is not very convincing if only a car costing millions is taken as an example in publicity. Aluminum alloy is very expensive and can only be applied to high-end products with relatively high profits. If it is used for all cars, there won't be any profit. Therefore, it's difficult to apply aluminum alloy to all cars. Also, there is difficulty in welding and repairing the all-aluminum body, especially after a collision. It is even cheaper to buy a new one than to repair it.

When the all-aluminum body was just launched, car companies used its safety performance as a selling point. However, after many traffic accidents, the result was not as simple as it was thought. It is undeniable that the strength of aluminum alloy is not low, but it is too easy to deform. Once there is external force, aluminum alloy will have a round shape. With the development of technology, hot-formed steel has better strength than aluminum alloy. Some top high-impact steels have a strength of 1800Mpa, and their density is much lower than ordinary steel, which can meet the requirements of weight reduction and safety. More importantly, the cost of a high-impact steel body is much lower than that of an all-aluminum body.

Of course, we can not equal the high-impact steel with aluminum alloy in terms of light weights. Therefore, high-impact steel will be used for the area requiring high-impact energy absorption, such as A-pillars and B-pillars, while aluminum alloy is used for the easily crushed area after weighing by car companies. By doing this, both safety and light weights can be taken into account.

Generally speaking, the advantages and disadvantages of the all-aluminum body are very obvious. It has an irreplaceable performance for the lightweight and handling performance of the vehicle, but the disadvantages are also fatal. In an era when people are increasingly concerned about car safety, the aluminum alloy body with high prices can not meet the existing safety standards; coupled with the shortcomings of difficult maintenance and high costs, the aluminum body is gradually not welcomed by the car market.

However, the new energy market has emerged, and the all-aluminum body has become a hot topic again in recent years. Because the curb weight of electric vehicles is much heavier than that of traditional fuel vehicles, aluminum alloys have become the first choice in order to reduce weights and increase continuation of the journey. For example, the NIO ES8 uses an all-aluminum body. Judging from the ES8's recent five-star evaluation in the E-NCAP crash test, it seems that with the iteration of technology, the safety performance of the all-aluminum body may also be overcome in the future.