The Influence of Low-Temperature Aging Heat Treatment on the Mechanical Properties of Al-Si Aluminum Alloy

On this page

Abstract: Using die-cast aluminum alloy AlSi7CuMnMg as the research subject, low-temperature aging heat treatment experiments were conducted, and the mechanical properties of the alloy were comprehensively analyzed by introducing the toughening index K. The results show that as the aging temperature increases (150–180 ℃) and the aging time extends (2–10 h), the yield strength of the alloy significantly improves, but its plasticity decreases. Considering the toughening index K, the optimal low-temperature aging process for the alloy is determined to be 170℃ for 6 hours. Under this heat treatment condition, the alloy's strength is improved while maintaining good plasticity. The tensile strength is 303MPa, the yield strength is 40.77% higher than that of the cast state, reaching 183MPa, and the elongation is 7.5%.

1. Effect of Different Aging Temperatures on Mechanical Properties of Alloy

Five groups of samples were subjected to different aging treatments, with an aging time of 6 hours and aging temperatures of 150, 160, 170, 180, and 190°C. The relationship between the mechanical properties and the aging treatment system is shown in Figure 2 and Table 3. As can be seen from Table 3, with an increase in aging temperature, the yield strength of the material increases significantly. When the aging temperature is 150°C, there is no obvious change compared to the die-cast state. When the temperature increases to 160°C, the yield strength reaches 160MPa, which is 22% higher than that of the sample at 150°C. When the aging temperature reaches 180°C, the yield strength of the sample increases to 189MPa, which is 45% higher than that in the die-cast state. As shown in Table 3, before the aging temperature rises to 170°C, the yield strength of the material increases as the temperature rises. After the aging temperature reaches 170°C, further increases in temperature cause little change in the yield strength. At 190°C, the alloy enters the over-aging stage, and the yield strength begins to decrease. The tensile strength of the material does not change significantly with increasing aging temperature, reaching a peak of 303MPa at an aging temperature of 170°C. Then, the tensile strength decreases, dropping to 281MPa at 190°C. As the aging temperature increases, the elongation decreases from 11% in the cast state to 4.3% at 190°C.

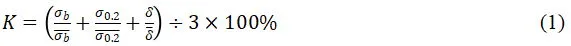

To better represent the influence of different heat treatment systems on the strength and plasticity of AlSi7CuMnMg alloy, the toughening index K is introduced. The value of K is calculated based on strength and plasticity. The higher the strength and the better the plasticity, the larger the K value becomes. Using the mechanical properties of AlSi7CuMnMg die-cast without heat treatment as the comparison standard, the mathematical expression of the toughening index K is as follows:

Where is the measured mechanical property value of the alloy after different heat treatment systems, and is the average mechanical property value of the alloy in the die-cast state. Table 3 shows the mechanical properties and toughening index of the AlSi7CuMnMg alloy in the die-cast state and at different aging temperatures after 6 hours of heat preservation. From Table 3, it can be seen that the toughening index K value of sample No. 3 is the highest, at 1.039, indicating that sample No. 3 has the best overall mechanical properties.

Table 3 Mechanical properties of AlSi7CuMnMg alloy at different aging temperatures

To better represent the influence of different heat treatment systems on the strength and plasticity of AlSi7CuMnMg alloy, the toughening index K is introduced. The value of K is calculated based on strength and plasticity. The higher the strength and the better the plasticity, the larger the K value becomes. Using the mechanical properties of AlSi7CuMnMg die-cast without heat treatment as the comparison standard, the mathematical expression of the toughening index K is as follows:

Where is the measured mechanical property value of the alloy after different heat treatment systems, and is the average mechanical property value of the alloy in the die-cast state. Table 3 shows the mechanical properties and toughening index of the AlSi7CuMnMg alloy in the die-cast state and at different aging temperatures after 6 hours of heat preservation. From Table 3, it can be seen that the toughening index K value of sample No. 3 is the highest, at 1.039, indicating that sample No. 3 has the best overall mechanical properties.

Table 3 Mechanical properties of AlSi7CuMnMg alloy at different aging temperatures

| Heat Treatment Process | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Toughening Index K |

| Die-Casting State | 130 | 295 | 11.0 | 1.000 |

| 150°C × 6 h | 131 | 290 | 9.6 | 0.953 |

| 160°C × 6 h | 160 | 295 | 7.4 | 0.968 |

| 170°C × 6 h | 183 | 303 | 7.5 | 1.039 |

| 180°C × 6 h | 189 | 299 | 6.0 | 1.004 |

| 190°C × 6 h | 183 | 281 | 4.4 | 0.917 |

2. Effect of Different Aging Times on the Mechanical Properties of the Alloy

The AlSi7CuMnMg alloy was subjected to low-temperature aging heat treatment at an aging temperature of 170°C, with aging times set to 2, 4, 6, 8, and 10 hours. Table 4 shows the mechanical properties of the AlSi7CuMnMg alloy under different aging treatment systems. As shown in Table 4, with the increase in low-temperature aging time, the yield strength of the material increases. After aging for 10 hours, the yield strength of the material reaches 198MPa, which is 52.3% higher than in the cast state, while the elongation shows a downward trend. The elongation after fracture of the material, after aging for 10 hours, is only 5.0%, which is 54% lower than in the cast state. The tensile strength of the material does not change significantly with increased holding time. As seen in Table 4, the toughening index K value of sample No. 3 remains the highest, indicating that when the aging temperature is 170°C, the optimal aging time is 6 hours.

Table 4 Mechanical properties of AlSi7CuMnMg alloy at different aging times

Table 4 Mechanical properties of AlSi7CuMnMg alloy at different aging times

| Heat Treatment Process | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation After Fracture (%) | Toughening Index K |

| Die Casting State | 130 | 295 | 11.0 | 1.000 |

| 170°C × 2 h | 148 | 281 | 7.8 | 0.932 |

| 170°C × 4 h | 167 | 291 | 6.0 | 0.938 |

| 170°C × 6 h | 183 | 303 | 7.5 | 1.039 |

| 170°C × 8 h | 190 | 305 | 5.7 | 1.004 |

| 170°C × 10 h | 198 | 307 | 5.0 | 1.008 |