The Effect of Aluminum Titanium Boron Refining Agents on Mechanical Properties of Aluminum Die Castings

As the design of die castings becomes more and more complex, the quality requirements are getting higher and higher. In the manufacturing process, although some advanced processes are used, such as using mold temperature machines to ensure the stability of the mold temperature, high-pressure point cooling machines and partial extrusion for eliminating partial shrinkage, and vacuum die casting to reduce the internal holes of the die casting part. However, for the thick-walled parts with strict requirements, the above measures cannot completely solve the die casting defects such as shrinkage and thermal cracking due to the complexity of some die casting parts, resulting in a high rejection rate of die castings, which puts great pressure on production costs.

The Al-Ti-B refining agent is added for the aluminum alloy liquid to refine the die casting aluminum alloy liquid, improving the internal structure of the aluminum liquid, reducing the shrinkage in the solidification process, and ensuring the compactness of the internal structure of the die casting. The metallographic structure, appearance and mechanical properties of die castings were compared before and after the addition of Al-Ti-B refining agent to verify the effectiveness and feasibility of the process.

The Al-Ti-B refining agent is added for the aluminum alloy liquid to refine the die casting aluminum alloy liquid, improving the internal structure of the aluminum liquid, reducing the shrinkage in the solidification process, and ensuring the compactness of the internal structure of the die casting. The metallographic structure, appearance and mechanical properties of die castings were compared before and after the addition of Al-Ti-B refining agent to verify the effectiveness and feasibility of the process.

1. The adding process of the Al-Ti-B refining agent

1.1 Chemical composition of AlSi9Cu3 aluminum alloys and Al-Ti-B refining agents

1.1.1 The chemical composition and mechanical properties of AlSi9Cu3 aluminum alloys

The chemical composition standards and actual test values of AlSi9Cu3 aluminum alloys are shown in Table 1, and their mechanical property standards and actual test values are shown in Table 2. The impact of adding Al-Ti-B refining agents on the original chemical composition and mechanical properties is analyzed through experiments.

Table 1 Chemical composition of AlSi9Cu3 alloy wb/%

1.1.1 The chemical composition and mechanical properties of AlSi9Cu3 aluminum alloys

The chemical composition standards and actual test values of AlSi9Cu3 aluminum alloys are shown in Table 1, and their mechanical property standards and actual test values are shown in Table 2. The impact of adding Al-Ti-B refining agents on the original chemical composition and mechanical properties is analyzed through experiments.

Table 1 Chemical composition of AlSi9Cu3 alloy wb/%

| Si | Cu+ | Fe | Mn | Mg | Sn | Ni | Zn | Cr | Ti | Al | |

| Standard values | From 8.0 to 11.0 | From 2.0 to 4 0 | Less than and equal to 1.30 | Less than and equal to 0.55 | From 0.05 to 0.55 | Less than and equal to 0.150 | Less than and equal to 0.55 | Less than and equal to 1.2 | Less than and equal to 0.10 | Less than and equal to 0.25 | The rest |

| Actual values | 10.0792 | 2.1450 | 1.0870 | 0.2248 | 0.1587 | 0.0125 | 0.0543 | 0.3518 | 0.0253 | 0.0790 | The rest |

Table 2 Mechanical properties of AlSi9Cu3 alloys

| Items | Tensile strength/MPa | Elongation/% |

Yield strength/MPa | Hardness (HVW) |

| Standard values | Greater than and equal to 240 | Greater than and equal to 1.0 | Greater than and equal to 140 | Greater than and equal to 80 |

| Actual values | 275 | 1.2 | 160 | 82 |

1.1.2 Chemical composition of Al-Ti-B refining agents used in the test

Al-5Ti-1B was selected for Al-Ti-B refining agents used for the test, whose composition is shown in Table 3. The test was carried out under the condition that the chemical composition of A was stable and consistent.

Table 3: Chemical composition of Al-5Ti-1B wire wb/%

| Si | Fe | Ti | V | B | |

| Al-5Ti-1B | Smaller than and equal to 0.15 | Smaller than and equal to 0.2 | From 4.8 to 5.2 |

Smaller than and equal to 0.05 | From 0.9 to 1.1 |

1.2 Adding process requirements for Al-5Ti-1B refining agents

According to the requirements for die casting melting processes at the scene and die casting processes in the production workshop, as well as the temperature of Al-5Ti-1B wire, the relevant conditions of the adding process and method are unified to ensure the stability of the test process. See Table 4.

Table 4 Main smelting and casting process parameters

| The heating temperature of the Al-5Ti-1B wire/℃ | The melting aluminum temperature/℃ | The holding temperature of the side furnace | The method of adding the Al-5Ti-B wire | The amount of the Al-5Ti-B wire % | Refining and degassing time/min |

| From 200 to 300 | From 720 to 760 | From 650 to 660 | Putting into the aluminum liquid tank | From 0.2 to 0.3 | 10 |

2. The influence of adding Al-Ti-B refining agents and holding time on the microstructure of aluminum alloys

Aluminum alloys usually have three kinds of grain morphology under the metallographic phase, namely columnar crystals, equiaxed crystals and fine-grained structure. Columnar crystals seriously affect the strength and toughness of the material. The small equiaxed crystals will reduce the tendency of hot cracking, but the coarse equiaxed crystals will also reduce the mechanical properties of the material. In the process of aluminum alloy die casting, leftovers will be produced. The leftovers will be used as remelting material according to a certain proportion and then used again. In the process of repeated remelting, the quality of the aluminum alloy liquid will be reduced, which will affect the mechanical property of the alloy. Therefore, by adding Al-5Ti-1B refining agents, the structure is refined and the quality of molten aluminum is improved. After adding Al-5Ti-1B refining agents, the holding time of the aluminum alloy liquid is compared with its recession effect to finally determine the best deterioration time.

2.1 A comparison before and after adding Al-5Ti-1B refining agents

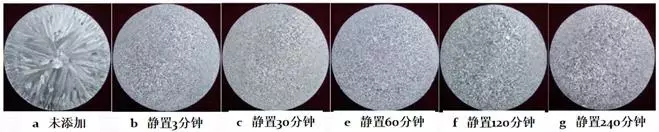

The structure of the aluminum alloy liquid before and after adding Al-Ti-B refining agents is shown in Figure 1 by sampling and comparative analysis. It can be seen that the internal structure of the sample with Al-5Ti-1B refining agents is relatively fine, while the grain without Al-Ti-B refining agent is relatively coarse. Moreover, as the amount of addition increases, the grain size is further refined.

Figure 1 Metallographic structure of aluminum alloys before and after adding Al-Ti-B refining agents

2.2 The impact of holding time on the grain size of aluminum alloy after deterioration

Figure 2 The effect of holding time on grain sizes after adding Al-Ti-B refining agents

After adding Al-Ti-B refining agents to the aluminum alloy liquid, samples with different holding time were taken, polished, and corrosion observed, as shown in Figure 2. It can be seen that the fracture surface grains of the samples without Al-Ti-B are coarse, and after the addition of Al-Ti-B refining agents; as the holding time increases, the cross-sectional grain of the samples becomes smaller.

3. The effect of Al-Ti-B refining agents on partial shrinkage of die casting defects

In the aluminum alloy die casting process, the wall thickness of the die casting is not very uniform, and defects such as shrinkage holes and shrinkage pits often appear at the transition position between the thin wall and thick wall, or the thick wall position. In this test, combined with the casting defects in the die casting on site, check whether there is an effect of adding Al-5Ti-1B refining agents to the die casting aluminum liquid and after the internal structure of the aluminum alloy liquid being refined on the shrinkage holes and shrinkage pits of the die casting part.

3.1 The effect of adding Al-Ti-B refining agent on shrinkage pits and shrinkage cracks of the product's appearance

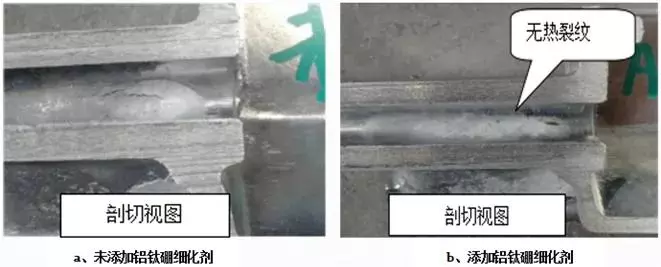

Figure 3 The effect of adding Al-Ti-B refining agents on casting defects before and after

Figure 3 shows the effect of adding Al-5Ti-1B refining agents on casting defects before and after. It can be seen that the die casting parts produced by the aluminum alloy liquid without adding the Al-5Ti-1B refining agent have obvious pits and shrinkage cracks caused by shrinkage, while the shrinkage pits and shrinkage cracks in the same part disappeared for the aluminum alloy liquid after adding the Al-5Ti-1B refining agent. The qualification rate of the product increased greatly, as shown in Table 5.

Table 5 A comparison of qualification rates before and after adding Al-Ti-B refining agents

| Items | Products | Inspected numbers/pieces | Scrapped numbers due to shrinkage/pieces | Qualified numbers/pieces | Qualification rates/% | Notes |

| 1 | Filter shells | 550 | 20 | 530 | 96.36 | Without adding Al-Ti-B refining agents |

| 580 | 2 | 578 | 99.66 | Adding Al-Ti-B refining agents | ||

| 2 | D058 main shells | 480 | 34 | 446 | 92.91 | Without adding Al-Ti-B refining agents |

| 430 | 3 | 427 | 99.30 | Adding Al-Ti-B refining agents |

3.2 A comparison of shrinkage porosity and shrinkage cavity in the product by adding Al-Ti-B refining agents

Figure 4 The effect of Al-Ti-B refining agent on the internal shrinkage of die castings before and after adding Al-Ti-B refining agents

By comparing before and after cutting the wall thickness parts that are prone to shrinkage, as shown in Figure 4, it can be seen that the die castings produced by aluminum alloy liquid without adding Al-5Ti-1B refining agents have obvious shrinkage, while the shrinkage cavity of products produced from aluminum alloy liquid with 5Ti-1B refining agent is significantly improved. See Table 5.

4. The effect of adding Al-Ti-B refining agents on the mechanical properties of aluminum alloys

Table 6 Changes in mechanical properties of aluminum alloy liquid before and after adding Al-Ti-B refining agents

| Items | Tensile strength/MPa | Elongation/% | Yield strength/MPa | Hardness (HVW) |

| Standard values | Greater than and equal to 240 | Greater than and equal to 1.0 | Greater than and equal to 140 | Greater than and equal to 80 |

| Adding A1-Ti-B refining agents | 275 | 1.2 | 160 | 82 |

| Without A1-Ti-B refining agents | 288 | 1.6 | 176 | 87 |

According to the comparative data of the mechanical properties before and after adding Al-Ti-B refining agents to the aluminum alloy liquid. See Table 6. It can be seen that the die castings produced by the aluminum alloy liquid with the Al-5Ti-1B refining agents have better mechanical properties than those without Al-Ti-B refining agents.