Tesla Model Y Body Is Manufactured by Single-casting (Part One)

The Swedish girl Simone Giertz, a YouTube blogger, cut off the rear of Tesla's trunk and roof and converted the Model 3 into a pickup truck, which she called a Truckla.

Simone Giertz doesn't need to worry now, because Tesla's SUV is really here. It is Model Y. It has been circulated that a single-casting is adopted for Model Y. While people are guessing, Model Y has become the product coming as a shock for people in Tesla's history.

The Model 3 body

In the early years, the CEO of Munro & Associates named Sandy Munro from an American engineering consulting company took 6,600 hours to reversely disassemble two sets of Model 3. At the same time, the company's veteran engineer and his team disassembled the Tesla Model 3, BMW i3 and Chevrolet Bolt respectively, and compared them. They discovered the fatal design flaws of the Tesla Model 3. Manufacturability was not considered for designing bodies, weights and matching bulkheads, and the Model 3 body in white was seriously over designed.

Tesla's original intention was to improve the passive safety of Model 3 through the enhanced design of various parts of the structure. In an interview with CBS in April 2018, Elon admitted for the first time that the manufacturing complexity of Model 3 made the fully automated production line difficult, and the role of humans in the manufacturing process was underestimated. What Elon didn't say was that because of complex manufacture of the body in white, the person being in charge of the Model 3 body in white was fired by him.

A comparison of Model 3 and Model Y

Undoubtedly, Model Y will definitely make a breakthrough in the design of Model 3. A few days ago, Elon Musk who is the CEO of Tesla hyped the Tesla Model Y to be manufactured in Germany and claimed that this would be a revolution in car body engineering. Musk said that Tesla successfully integrated 70 parts in Model 3 into 2 parts in Model Y and this major improvement was just the beginning.

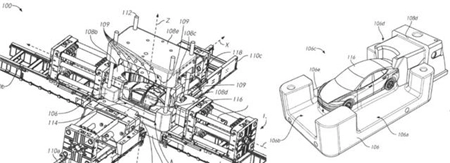

Tesla plans to use its new super large casting technology more widely throughout its electric vehicle product line. A patent application filed in 2019 showed Tesla's new casting machine which is used to make Model Y. Now, Musk said that this technology will be used more widely for the Model Y cars to be manufactured at the Gigafactory in Berlin.

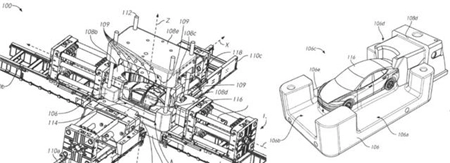

Tesla's new patent, namely a multi-directional integrated casting machine for car frames and related methods. Through this one-piece casting machine, the body of Model Y will be reduced from 70 parts to one part, greatly reducing the capital expenditure for assembling all parts together.

In Tesla's words, under normal circumstances, multiple die-cast machines are used for manufacturing different parts of the body for the body-in-white. For example, a die casting machine in a factory may be used for manufacturing a certain part. When these parts are produced, workers or robots need to weld them together to form a whole body in white.

However, these individual parts will also cause problems. For example, if a die casting machine is responsible for one part, then multiple machines need to be used for multiple parts. As a result, more capital costs and time costs will be incurred during the manufacturing process. Therefore, Tesla invented this patent, which can reduce manufacturing related costs, including but not limited to factory operating costs, tool costs (the amount of equipment), time costs and labor costs. If only two parts are included, they will be reducing the time cost and capital cost.

Simone Giertz doesn't need to worry now, because Tesla's SUV is really here. It is Model Y. It has been circulated that a single-casting is adopted for Model Y. While people are guessing, Model Y has become the product coming as a shock for people in Tesla's history.

The Model 3 body

In the early years, the CEO of Munro & Associates named Sandy Munro from an American engineering consulting company took 6,600 hours to reversely disassemble two sets of Model 3. At the same time, the company's veteran engineer and his team disassembled the Tesla Model 3, BMW i3 and Chevrolet Bolt respectively, and compared them. They discovered the fatal design flaws of the Tesla Model 3. Manufacturability was not considered for designing bodies, weights and matching bulkheads, and the Model 3 body in white was seriously over designed.

Tesla's original intention was to improve the passive safety of Model 3 through the enhanced design of various parts of the structure. In an interview with CBS in April 2018, Elon admitted for the first time that the manufacturing complexity of Model 3 made the fully automated production line difficult, and the role of humans in the manufacturing process was underestimated. What Elon didn't say was that because of complex manufacture of the body in white, the person being in charge of the Model 3 body in white was fired by him.

A comparison of Model 3 and Model Y

Undoubtedly, Model Y will definitely make a breakthrough in the design of Model 3. A few days ago, Elon Musk who is the CEO of Tesla hyped the Tesla Model Y to be manufactured in Germany and claimed that this would be a revolution in car body engineering. Musk said that Tesla successfully integrated 70 parts in Model 3 into 2 parts in Model Y and this major improvement was just the beginning.

Tesla plans to use its new super large casting technology more widely throughout its electric vehicle product line. A patent application filed in 2019 showed Tesla's new casting machine which is used to make Model Y. Now, Musk said that this technology will be used more widely for the Model Y cars to be manufactured at the Gigafactory in Berlin.

Tesla's new patent, namely a multi-directional integrated casting machine for car frames and related methods. Through this one-piece casting machine, the body of Model Y will be reduced from 70 parts to one part, greatly reducing the capital expenditure for assembling all parts together.

In Tesla's words, under normal circumstances, multiple die-cast machines are used for manufacturing different parts of the body for the body-in-white. For example, a die casting machine in a factory may be used for manufacturing a certain part. When these parts are produced, workers or robots need to weld them together to form a whole body in white.

However, these individual parts will also cause problems. For example, if a die casting machine is responsible for one part, then multiple machines need to be used for multiple parts. As a result, more capital costs and time costs will be incurred during the manufacturing process. Therefore, Tesla invented this patent, which can reduce manufacturing related costs, including but not limited to factory operating costs, tool costs (the amount of equipment), time costs and labor costs. If only two parts are included, they will be reducing the time cost and capital cost.