Research on European Automotive Aluminum Alloy Technologies

Overall material and lightweight situations

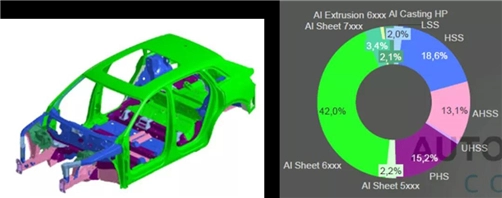

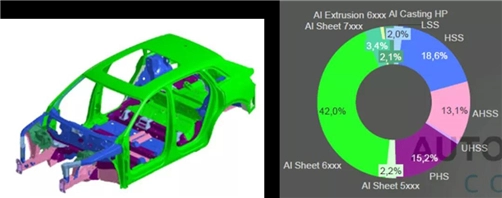

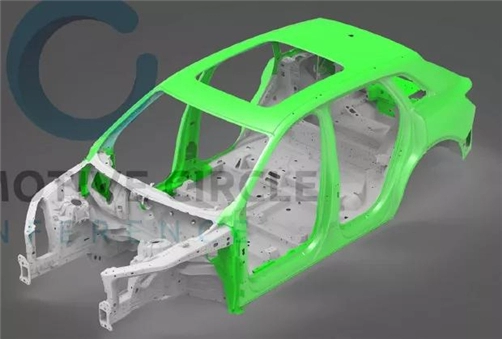

The following is a schematic diagram of the Audi e-tron body-in-white structure with the updated design. The different colors show the parts made of different materials.

The body is mainly made from steel-aluminum. Among them, the amount of traditional mild steel is 2%, high-impact steel, advanced high-impact steel, ultra-high-impact steel and hot-formed steel 47.5% and aluminum alloy as high as 50.4%.

The total weight of the white body is 399 kg, including the weights of four doors, two covers and other covering parts, as well as the unpainted body of the bumper beam. The skeleton weight is 326.9 kg. The total weight of the white body 2019 version is 478.1kg, and the weight of the skeleton is 406 kg. The total weight of the body-in-white and frame weight of the new generation of models is reduced by 16.5% and 19.5%.

The torsional stiffness of the body-in-white without the battery frame is 45.1kNm/°, and the lightweight factor is 1.5, which is 0.18 lower than the 2019 version.

The analysis of the lightweight technology

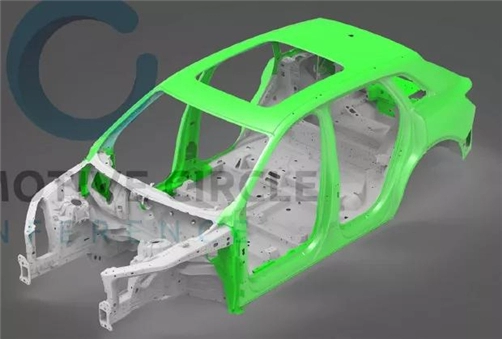

Up to 50.4% of aluminum alloy are mainly used for four doors, two covers and some body-in-white parts. Among them, the main aluminum parts for body-in-white include side walls, A pillars, B pillars, and roofs.

Aluminum alloy top covers

The updated Audi e-tron uses 6 series of aluminum alloys to make the top cover and front and rear side beams, and the 7 series of aluminum alloys are adopted by the hot forming process to make the top cover's side beams. While applying lightweight materials, the structural design is optimized and the design parts are integrated. The A-pillar, roof reinforcement plate and crossbeam joint are integrated into an aluminum alloy hot-formed part, and the design of the front reinforcement crossbeam is modified to reduce the intermediate reinforcement. In the end, 6 parts were reduced; the weight was reduced by 28.3 kg, and the weight reduction ratio was as high as 41.8%.

The application of aluminum alloy top covers not only reduces weights, but more importantly, it can meet or possibly exceed performance standards. The aluminum top cover meets or improves the safety, NVH, and durability properties of steel top covers. The aluminum top cover’s rigidity is 5Hz (12%) higher than that of the steel vehicle. The aluminum top cover's torsional rigidity is 3kNm/° higher than that of the original steel body.

In addition, through forming and connecting technology, the number of parts and joints is reduced, and a better welding effect is obtained. With the application of 7 series hot-formed aluminum alloy B-pillars and rolled thresholds, the compression of the top cover can be met. Aluminum top covers require fewer components and joints than steel top covers, which can reduce the time and cost of vehicle assembly.

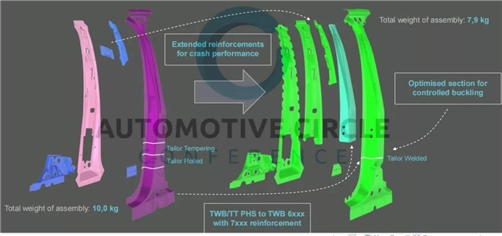

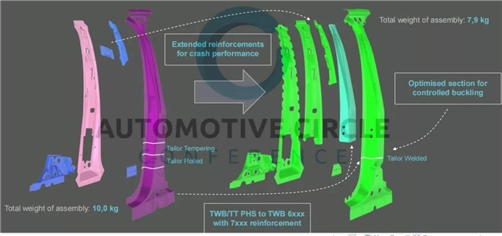

The application of thermoforming

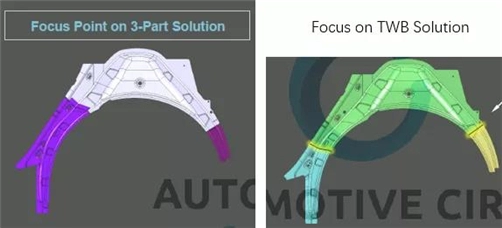

In order to meet the requirements for the safety performance of car bodies, the updated Audi e-tron adopts two hot forming technologies, that is, steel hot forming and aluminum hot forming. The steel hot-formed parts mainly include the front wall, the middle longitudinal beam, the seat mounting beam, and the rear longitudinal beam. Aluminum hot-formed parts mainly include A-pillar inner and outer plates, and B-pillar. The A-pillar assembly uses 7 series of aluminum alloys, the B-pillar outer plate 6 series of laser-welded aluminum alloy plates, and the reinforcement plate 7 series of aluminum alloys. The weight of the B-pillar assembly is reduced by 21%.

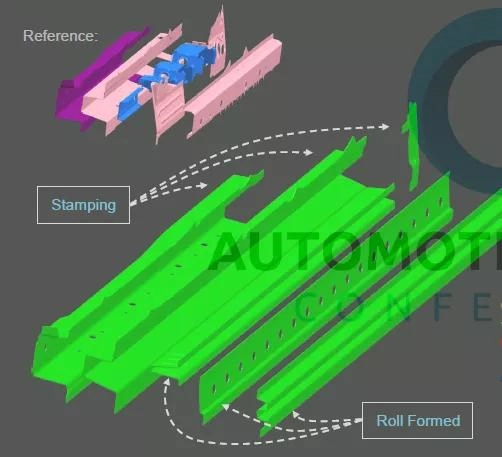

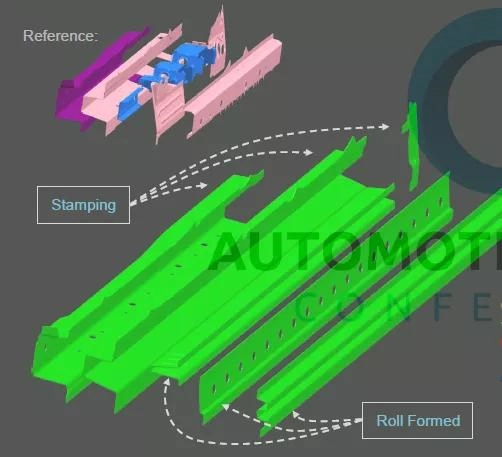

The application of aluminum alloy roll forming technologies

The Audi e-tron with updated design applied rolling technology to make parts of the threshold, replacing the steel parts of the previous generation. The weight was saved by 13.2 kg (with a reduction of 31% ), and the number of parts was reduced from 8 to 6.

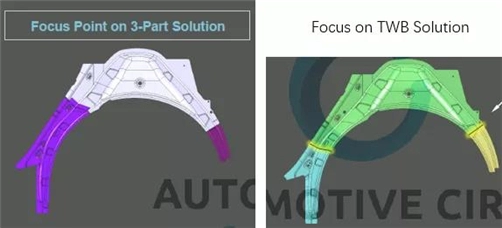

The application of Laser Welding Technologies

The updated Audi e-tron has applied laser welding technologies in two places, one is the B-pillar outer plate mentioned above, and the other is the rear wheel cover. The advantage of applying laser welding to the outer plate of the B-pillar is that it is accurately designed to meet the requirements of the side impact. The advantage of using laser welding at the wheel cover is to reduce the investment for molds and make full use of waste.

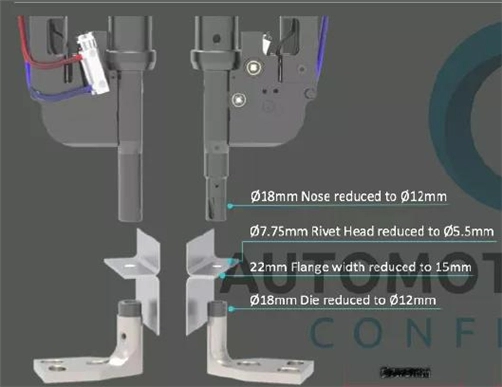

The innovation of connecting technology promoting the lightweight

The updated Audi e-tron body is mainly made of steel-aluminum. In addition to traditional spot welding, glue welding and MIG welding, laser welding, friction stir welding, self-piercing riveting, non-rivet connection and crimping are also used.

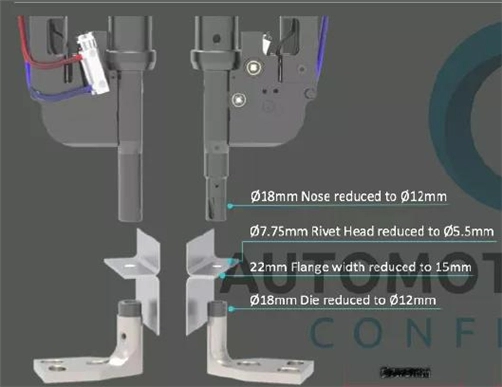

The A-pillar adopts small-size rivet riveting technology. The diameter of the rivet is reduced from 5.3 mm to 4 mm, and the overlapping edge is reduced from 22 mm to 15 mm. The application of this technology causes a weight reduction of 40% in the A-pillar area.

The main advantages of Audi e-tron with updated design are as follows compared with the previous model:

① The aluminum top cover is used, which reduces 6 parts compared to the steel top cover, and reduces the weight by 41.8%.

② The use of hot-formed steel and 7 series of hot-formed aluminum alloys effectively improve safety.

③ Rolling technology is used to reduce the number of parts and the weight of the assembly.

④ Laser welding technology is used to optimize the design and effectively use waste materials to reduce costs.

⑤ Use rivets with small sizes to reduce the width of the overlapped edge and achieve the purpose of lighter weights.

Outlook

Although the report on the ECB is not an OEM mass-produced model, it brings cutting-edge technical information. Alumobility's research closely follows the trend of lightweight technology and combines its technical resources to develop successful solutions to OEMs. The research on the application of aluminum alloy technology that is ahead of mass production undoubtedly provides OEMs with solutions for automotive aluminum. With the clear goal of dual carbon, the demand for lightweight is increasing.

The following is a schematic diagram of the Audi e-tron body-in-white structure with the updated design. The different colors show the parts made of different materials.

The body is mainly made from steel-aluminum. Among them, the amount of traditional mild steel is 2%, high-impact steel, advanced high-impact steel, ultra-high-impact steel and hot-formed steel 47.5% and aluminum alloy as high as 50.4%.

The total weight of the white body is 399 kg, including the weights of four doors, two covers and other covering parts, as well as the unpainted body of the bumper beam. The skeleton weight is 326.9 kg. The total weight of the white body 2019 version is 478.1kg, and the weight of the skeleton is 406 kg. The total weight of the body-in-white and frame weight of the new generation of models is reduced by 16.5% and 19.5%.

The torsional stiffness of the body-in-white without the battery frame is 45.1kNm/°, and the lightweight factor is 1.5, which is 0.18 lower than the 2019 version.

The analysis of the lightweight technology

Up to 50.4% of aluminum alloy are mainly used for four doors, two covers and some body-in-white parts. Among them, the main aluminum parts for body-in-white include side walls, A pillars, B pillars, and roofs.

Aluminum alloy top covers

The updated Audi e-tron uses 6 series of aluminum alloys to make the top cover and front and rear side beams, and the 7 series of aluminum alloys are adopted by the hot forming process to make the top cover's side beams. While applying lightweight materials, the structural design is optimized and the design parts are integrated. The A-pillar, roof reinforcement plate and crossbeam joint are integrated into an aluminum alloy hot-formed part, and the design of the front reinforcement crossbeam is modified to reduce the intermediate reinforcement. In the end, 6 parts were reduced; the weight was reduced by 28.3 kg, and the weight reduction ratio was as high as 41.8%.

The application of aluminum alloy top covers not only reduces weights, but more importantly, it can meet or possibly exceed performance standards. The aluminum top cover meets or improves the safety, NVH, and durability properties of steel top covers. The aluminum top cover’s rigidity is 5Hz (12%) higher than that of the steel vehicle. The aluminum top cover's torsional rigidity is 3kNm/° higher than that of the original steel body.

In addition, through forming and connecting technology, the number of parts and joints is reduced, and a better welding effect is obtained. With the application of 7 series hot-formed aluminum alloy B-pillars and rolled thresholds, the compression of the top cover can be met. Aluminum top covers require fewer components and joints than steel top covers, which can reduce the time and cost of vehicle assembly.

The application of thermoforming

In order to meet the requirements for the safety performance of car bodies, the updated Audi e-tron adopts two hot forming technologies, that is, steel hot forming and aluminum hot forming. The steel hot-formed parts mainly include the front wall, the middle longitudinal beam, the seat mounting beam, and the rear longitudinal beam. Aluminum hot-formed parts mainly include A-pillar inner and outer plates, and B-pillar. The A-pillar assembly uses 7 series of aluminum alloys, the B-pillar outer plate 6 series of laser-welded aluminum alloy plates, and the reinforcement plate 7 series of aluminum alloys. The weight of the B-pillar assembly is reduced by 21%.

The application of aluminum alloy roll forming technologies

The Audi e-tron with updated design applied rolling technology to make parts of the threshold, replacing the steel parts of the previous generation. The weight was saved by 13.2 kg (with a reduction of 31% ), and the number of parts was reduced from 8 to 6.

The application of Laser Welding Technologies

The updated Audi e-tron has applied laser welding technologies in two places, one is the B-pillar outer plate mentioned above, and the other is the rear wheel cover. The advantage of applying laser welding to the outer plate of the B-pillar is that it is accurately designed to meet the requirements of the side impact. The advantage of using laser welding at the wheel cover is to reduce the investment for molds and make full use of waste.

The innovation of connecting technology promoting the lightweight

The updated Audi e-tron body is mainly made of steel-aluminum. In addition to traditional spot welding, glue welding and MIG welding, laser welding, friction stir welding, self-piercing riveting, non-rivet connection and crimping are also used.

The A-pillar adopts small-size rivet riveting technology. The diameter of the rivet is reduced from 5.3 mm to 4 mm, and the overlapping edge is reduced from 22 mm to 15 mm. The application of this technology causes a weight reduction of 40% in the A-pillar area.

The main advantages of Audi e-tron with updated design are as follows compared with the previous model:

① The aluminum top cover is used, which reduces 6 parts compared to the steel top cover, and reduces the weight by 41.8%.

② The use of hot-formed steel and 7 series of hot-formed aluminum alloys effectively improve safety.

③ Rolling technology is used to reduce the number of parts and the weight of the assembly.

④ Laser welding technology is used to optimize the design and effectively use waste materials to reduce costs.

⑤ Use rivets with small sizes to reduce the width of the overlapped edge and achieve the purpose of lighter weights.

Outlook

Although the report on the ECB is not an OEM mass-produced model, it brings cutting-edge technical information. Alumobility's research closely follows the trend of lightweight technology and combines its technical resources to develop successful solutions to OEMs. The research on the application of aluminum alloy technology that is ahead of mass production undoubtedly provides OEMs with solutions for automotive aluminum. With the clear goal of dual carbon, the demand for lightweight is increasing.