Lightweight Aluminum Alloy Cars and Their New Welding Technologies (Part Two)

3. The new welding technology of aluminum alloy automobiles

3.1 The laser welding technology of aluminum alloys

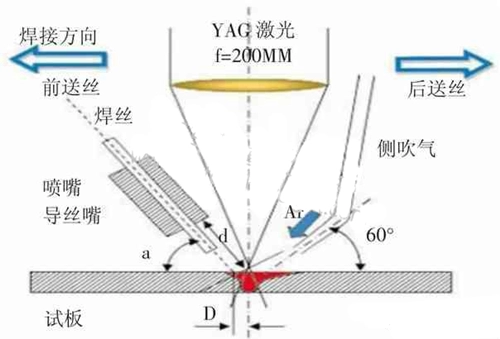

Compared with the traditional welding technology, the laser welding has the characteristics of relatively small welding seams, fast welding speeds and small thermal strain, which can greatly reduce the weight of automobiles. With the continuous improvement and development of laser processing equipment, the rapid development of the aluminum alloy laser welding technology is promoted. When a welding length of 20 to 30 meters is performed especially, the laser welding can completely replace resistance welding and MAG. Its welding principle is shown in Figure 1.

Figure 1 The laser welding technology of aluminum alloys

The advantages of the laser welding technology include the following aspects:

3.1 The laser welding technology of aluminum alloys

Compared with the traditional welding technology, the laser welding has the characteristics of relatively small welding seams, fast welding speeds and small thermal strain, which can greatly reduce the weight of automobiles. With the continuous improvement and development of laser processing equipment, the rapid development of the aluminum alloy laser welding technology is promoted. When a welding length of 20 to 30 meters is performed especially, the laser welding can completely replace resistance welding and MAG. Its welding principle is shown in Figure 1.

Figure 1 The laser welding technology of aluminum alloys

The advantages of the laser welding technology include the following aspects:

(1) Low welding costs: The construction environment requirement of laser welding is relatively low. It does not need to be in a vacuum and electrode environment, and strictly cleaning is not required before welding, which effectively reduces the cost and man-hours of welding.

(2) Good welding quality: Using the laser welding technology can reach a power of 105 to 109W/cm2, and good welding quality can be obtained due to the advantages of low heat input, relatively small heat-affected areas, great penetration, high energy density, small welding seams, and fast cooling speeds.

(3) Wide applications: The laser welding technology is a technology that can be welded without contact. The object to be welded will not be affected by electromagnetism at all, and the sealed object can be internally welded without disassembly, so that the welded object has a certain degree of manufacturability, and precise control and automation of welding can be realized with the cooperation of a manipulator and a computer.

3.2 Laser-arc hybrid welding technology

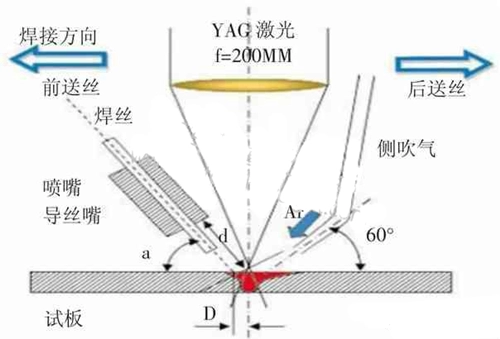

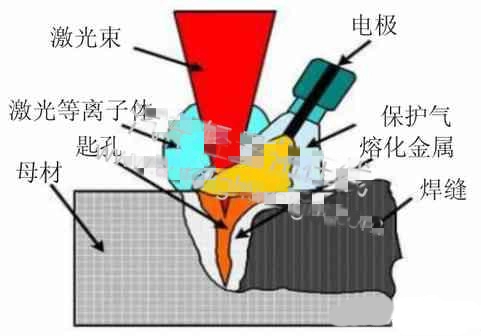

The laser-arc hybrid welding technology is a welding method proposed by foreign scholars in the late 1970s, and its welding principle is shown in Figure 2. The plasma generated above the molten pool due to the existence of the laser plays an important role in the stability of the arc. It can not only effectively reduce the reflection of the laser beam on the metal surface, but also absorb the light of the arc plasma, thereby improving the overall transmission efficiency of the laser beam. This technology combines the advantages of arc and laser.

Figure 2 The laser-arc hybrid welding technology

The advantages of the laser-arc hybrid welding technology mainly include the following aspects:

① Good welding performance: The laser-arc hybrid welding technology combines the advantages of laser and arc, and has the characteristics of wide heating ranges and high energy density, thereby obtaining high density and high energy heat input, and effectively reducing the appearance of welding cracks.

② More stable welding effect: If the welding process is too fast, the anode spot will become unstable, which will cause the arc to drift. However, the existence of the laser will provide good conditions for the arc to form the corresponding anode spot. Therefore, there will be a stable state due to the combination of laser and arc, even in the case of high-speed welding.

③ High heat utilization rates: The plasma generated by the laser beam in the welding zone is diluted due to the influence of the arc, reducing the radiation and absorption of laser energy by the plasma, and the molten aluminum alloy surface generated by the arc has a certain promoting effect on the absorption of laser energy, thus continuously improve the laser's utilization rate.

3.3 Friction stir welding technology

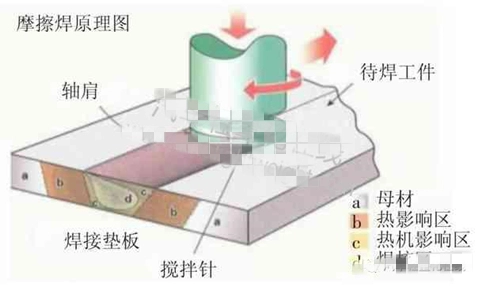

Friction stir welding technology was developed in the United Kingdom. Its working principle is shown in Figure 3. The stirring head with special properties is inserted into the workpiece to cause friction between the high-speed rotating stirring head and workpiece, and the generated heat is used to perform thermoplasticity on the metal. In addition, the front end is subjected to pressure to cause the plastic flow to the rear end in the process of stirring, thereby completing the entire pressure welding process.

Figure 3 The friction stir welding technology

The use of the friction stir welding technology has the following advantages:

- There will be no smoke or spatter in the welding process, and no harmful light will appear during the entire operation, such as infrared rays and ultraviolet rays.

- There will be no deformation after welding. Because the temperature of stir welding is low, the residual stress after welding is much smaller than that of fusion welding. There is no deformation in the thermoplastic process, so there will be no deformation after the welding is completed.

- There is a wide range of applications. All aluminum alloy materials can be welded, and the friction stir welding technology is not restricted by any shaft parts. Joint welding with various forms can be used, for example, butt welding.

- The welding cost is low. When the stir welding is performed, there is no need to consume welding wire, shielding gas, welding flux, welding rods and other materials. In addition, the oxide film on the surface of the aluminum alloy needs to be removed for the traditional welding method, but the stir welding only requires the grease on the surface of the welded object to be removed, which not only can effectively reduce energy consumption, but also there is relatively small pollution, providing an important guarantee for the lightweight of automobiles.

4. Conclusion

In summary, with the advancement of social economy and development of science and technology, people's living standards have been continuously improved, and the use of cars has become more and more common. A car has become one of the important means of transportation for people to travel. However, there will be a new challenge to the production of automobiles due to the relative shortage of energy in China and complying with the strategic goals of green and environmental protection. It is necessary to rationally use aluminum alloys to make the automobile develop in the direction of light weights, and to effectively use the new welding technology to maximize energy consumption to a certain degree, and provide a certain technical guarantee for the realization of automobile lightweight.

At present, lightweight is undoubtedly the top priority for the development of the automotive industry. In recent years, whether it is the application of new materials, the renewal of manufacturing processes or changes in structural design, lightweight can be said to have brought earth-shaking changes to the automobile manufacturing industry. For automakers, a set of practical lightweight solutions that comprehensively consider factors such as enterprise operation, resource utilization, and cost control will develop more business for them.

In summary, with the advancement of social economy and development of science and technology, people's living standards have been continuously improved, and the use of cars has become more and more common. A car has become one of the important means of transportation for people to travel. However, there will be a new challenge to the production of automobiles due to the relative shortage of energy in China and complying with the strategic goals of green and environmental protection. It is necessary to rationally use aluminum alloys to make the automobile develop in the direction of light weights, and to effectively use the new welding technology to maximize energy consumption to a certain degree, and provide a certain technical guarantee for the realization of automobile lightweight.

At present, lightweight is undoubtedly the top priority for the development of the automotive industry. In recent years, whether it is the application of new materials, the renewal of manufacturing processes or changes in structural design, lightweight can be said to have brought earth-shaking changes to the automobile manufacturing industry. For automakers, a set of practical lightweight solutions that comprehensively consider factors such as enterprise operation, resource utilization, and cost control will develop more business for them.