Die-cast Mold Design for Engine Chain Covers

With the rapid development of the automobile industry, the use of aluminum alloy die castings has increased significantly. To achieve energy conservation and emission reduction, the design of die castings has evolved towards multi-function and multi-part combinations. As a result, the wall thickness in thick areas of the die casting, easily producing shrinkage holes, shrinkage porosity, and other casting defects. To meet the functional requirements of the parts, methods such as local pressurization, semi-solid die casting, and insert die casting are often used to improve the casting’s internal quality. This study focuses on the automobile engine chain cover introducing the casting structure and development difficulties of the automobile engine chain cover, and reasonably designing the casting pouring system and overflow system through process analysis and theoretical calculation. A bidirectional multi-branch runner is used to achieve rapid filling, meeting the appearance and internal quality requirements of the casting. The design of the pouring and overflow system of flat castings is introduced, and the shrinkage defect at the hoisting hole of the chain cover is solved using insert casting, aiming to provide a reference for production.

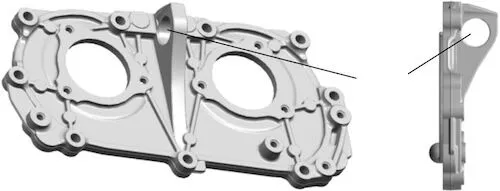

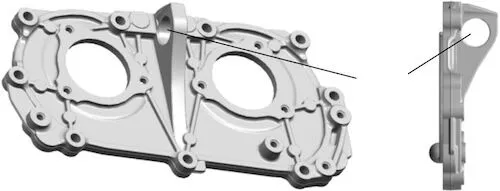

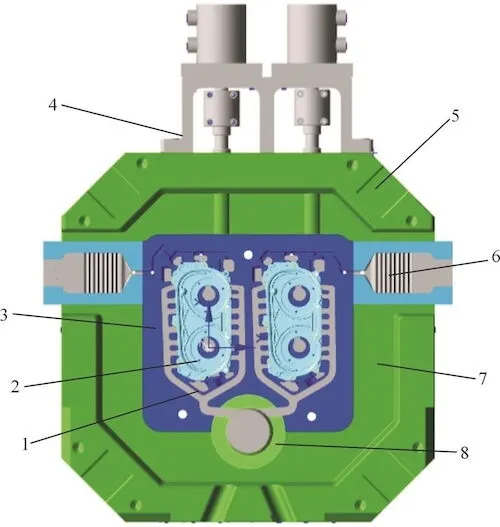

Figure 1 Chain covers

Figure 1 shows a specific type of automobile engine chain cover. The outer contour dimensions of the casting are 265 mm×133 mm×49 mm; the weight of a single piece is 480g, and the projected area is 261㎝2. The overall structure of the casting is flat and long, with an average wall thickness of 2.5 mm. There are 12 bolt mounting bosses around the periphery, a through hole with a diameter of 49.5 mm on each side of the middle, an arched bridge with a minimum width of 11 mm in the center, and a lifting hole with a diameter of 20 mm in the core.

The casting is made from Al-9Si-3Cu (Fe) alloy. The internal porosity specification requires that the maximum pore size at the ear is less than 2 mm, and in other parts, less than 0.8 mm. Leakages should be less than 3 mL/min under a pressure of 0.04 MPa. To meet the minimum wall thickness of the cavity, the maximum core pulling size of 10 mm will cause shrinkage cavity near the ear due to excessive wall thickness. Foreign countries use a production process with lateral core pulling from 10 mm to 20 mm. Due to the small size of the lateral core pulling, a large number of shrinkage holes form inside the casting. The machining allowance for the single-sided expansion hole is 5 mm. After machining, internal shrinkage holes are exposed on the surface of the lifting hole, affecting both the strength and appearance of the casting, resulting in a low yield rate. Given the above development difficulties, failure mode analysis was carried out in the early stages of development, and effective measures were taken. By rationally designing the pouring systems and adopting embedded casting processes, the internal quality issues of the casting were effectively resolved.

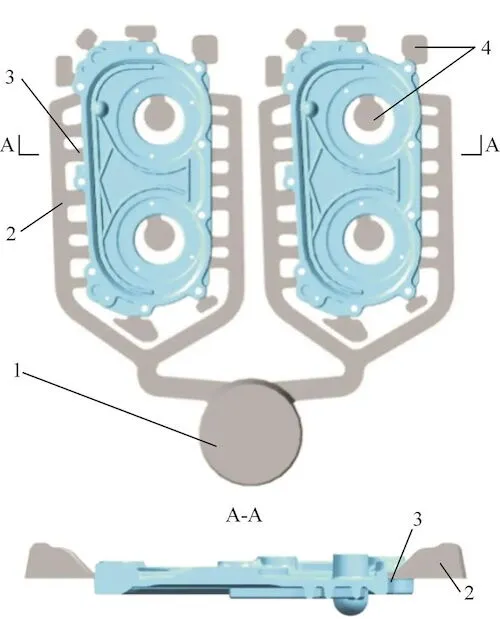

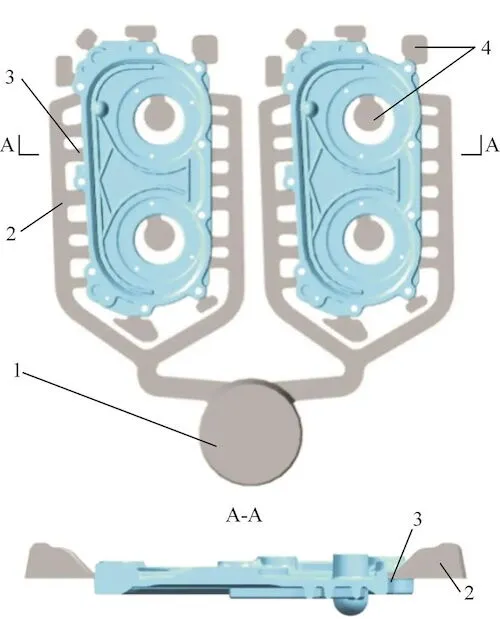

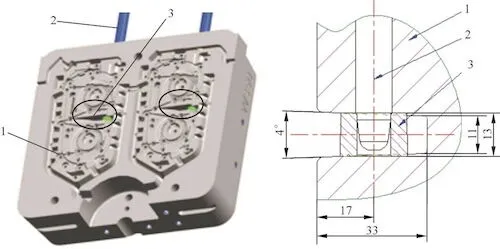

Figure 2 Pouring systems and overflow systems

1. Straight runners 2. Horizontal runners 3. Ingates 4. Overflow troughs

Table 1 Recommended values of overflow trough volumes

Figure 1 Chain covers

Figure 1 shows a specific type of automobile engine chain cover. The outer contour dimensions of the casting are 265 mm×133 mm×49 mm; the weight of a single piece is 480g, and the projected area is 261㎝2. The overall structure of the casting is flat and long, with an average wall thickness of 2.5 mm. There are 12 bolt mounting bosses around the periphery, a through hole with a diameter of 49.5 mm on each side of the middle, an arched bridge with a minimum width of 11 mm in the center, and a lifting hole with a diameter of 20 mm in the core.

The casting is made from Al-9Si-3Cu (Fe) alloy. The internal porosity specification requires that the maximum pore size at the ear is less than 2 mm, and in other parts, less than 0.8 mm. Leakages should be less than 3 mL/min under a pressure of 0.04 MPa. To meet the minimum wall thickness of the cavity, the maximum core pulling size of 10 mm will cause shrinkage cavity near the ear due to excessive wall thickness. Foreign countries use a production process with lateral core pulling from 10 mm to 20 mm. Due to the small size of the lateral core pulling, a large number of shrinkage holes form inside the casting. The machining allowance for the single-sided expansion hole is 5 mm. After machining, internal shrinkage holes are exposed on the surface of the lifting hole, affecting both the strength and appearance of the casting, resulting in a low yield rate. Given the above development difficulties, failure mode analysis was carried out in the early stages of development, and effective measures were taken. By rationally designing the pouring systems and adopting embedded casting processes, the internal quality issues of the casting were effectively resolved.

Figure 2 Pouring systems and overflow systems

1. Straight runners 2. Horizontal runners 3. Ingates 4. Overflow troughs

Table 1 Recommended values of overflow trough volumes

| Average wall thickness of castings/mm | The percentage of overflow groove volume in adjacent cavity area/% | |

| Low surface roughness of castings | Allowing a small amount of wrinkles on the casting surface | |

| 1.3 | 100 | 50 |

| 1.8 | 50 | 25 |

| 2.5 | 25 | 25 |

The overflow system of the die casting mold mainly includes an overflow trough and an exhaust channel, controlling the filling and flow state of the molten metal. The reasonable arrangement of the overflow system can effectively reduce casting defects such as cold shuts, flow marks, and gas holes. The design of the overflow trough and exhaust channel is related to factors such as casting structure and the pouring system’s structures and sizes. The overflow trough is generally arranged on the parting surface. The position where the molten metal first impacts, the last filled position, and where multiple strands of molten metal converge are selected. The exhaust duct is set at the rear end of the overflow trough to enhance overflow and exhaust effects. The structure of the chain cover mold is shown in Figure 3. The casting has one mold with two cavities for vertical discharge. Based on the calculation of the clamping force, a 9000 kN die-cast machine is selected. The pressure chamber is located 200 mm below the center of the mold. To form the lateral lifting hole of the casting, a hydraulic lateral core pulling mechanism is adopted, and a hydraulic cylinder is arranged above the mold to position the lifting hole insert. Since the shape of the casting cavity is relatively simple, the mold forming parts adopt an integral insert structure, simplifying the mold structure and facilitating the layout of the cooling water channel. The movable and fixed mold sleeves carry the forming parts, guide parts, and lateral core pulling mechanism, and bear the impact of the injection force during die casting.

The integral structure is adopted to make the mold structure simpler and more compact while ensuring functionality and strength. The ejection mechanism uses push rods for pushing. Since the casting is flat, the arrangement of the push rods aims to balance the ejection force on each part of the casting to prevent deformation. Therefore, to meet the ejection force, the number of push rods is increased, and 30 push rods with a diameter of 8 mm are set on each cavity of the movable mold insert, including 16 cavities, 9 runners, and 5 overflow grooves. The cooling system uses circulating water cooling and single-point water cooling according to the structural changes and positions of the casting.

Figure 3 Structure of chain cover die casting molds (movable molds)

1. Runners 2. Castings 3. Moving mold cavities 4. Upper hydraulic cylinders 5. Square guide columns 6. Exhaust channel inserts 7. Moving mold sleeves 8. Diverter cones

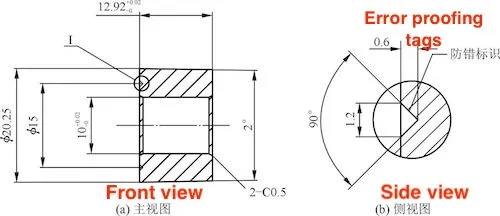

1. Moving mold cavities 2. Hydraulic positioning rods 3. Inserts

Figure 4 Insert casting structure

Figure 5 Inserts

The local volume near the 20 mm lifting hole at the lifting ear is thick and large, and the filling is slow, which easily causes air stagnation and shrinkage defects. To reduce shrinkage and loosening at the thick wall of the ear and improve the internal quality of the casting, the embedded casting process is adopted. Embedded casting involves placing the metal parts (inserts) in the die-casting mold first and then casting them together with the die-casting to eliminate local heat nodes, reduce wall thickness, and prevent shrinkage. Since the chain cover has a simple shape and structure, there is no obvious difference in the clamping force on both sides after the casting is parted at the maximum contour. Therefore, after determining the parting surface, the forming part of the chain cover ear hole that needs to be designed with a side core pulling structure is designed in the moving mold, and the precast hole core on the peripheral flange surface is also designed in the moving mold, which can increase the clamping force of the moving mold part and avoid the casting from being left in the fixed mold cavity after the mold is opened. This parting design places the insert in the moving mold cavity. To ensure that the insert is stable and reliable when the moving mold moves during the die-casting process, a reliable positioning and clamping method must be designed.

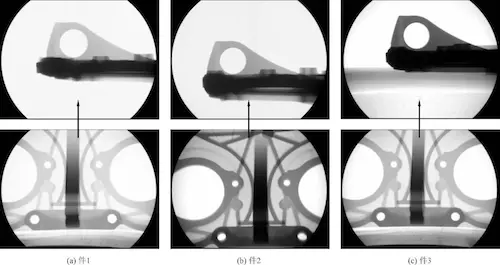

Figure 6 X-ray inspection image

The chain cover is a flat casting with a through hole in the center. It can be quickly filled by using a bidirectional multi-branch runner. Combined with a reasonable overflow system design, the casting can achieve excellent surface and internal quality. For castings with thick wall structures, when the core-pulling and partial pressurization processes cannot be effectively implemented due to the structure of the casting and the mold, the insert casting process can be used for die casting. The use of inserts for die casting production can eliminate partial heat nodes in the casting, reduce the wall thickness of the casting, and effectively prevent shrinkage cavities.