Cybertruck's One-piece Die-cast Body

Recently, there are some photos of the one-piece die-cast body of Tesla Cybertruck. The manufacturing plant for the Cybertruck one-piece die-cast body is located in Tesla's Texas Gigafactory in Austin.

Tesla Cybertruck can be said to be one of the most recognizable vehicles in the world. To create this peculiar car body, Tesla officially activated the world's largest die-cast machine, which means that it is a step closer to the mass production of Cybertruck.

In the past few years, Tesla has used one-piece die-cast technology to build the Model Y body. From the initial later half of the body, it has now developed into an integrated front and rear half to replace the original 70 kinds of parts, greatly reducing production costs and time.

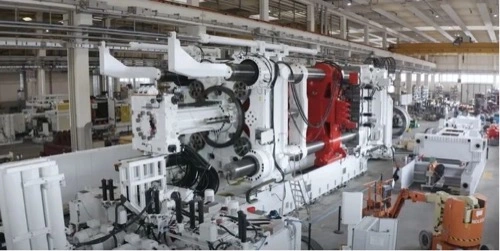

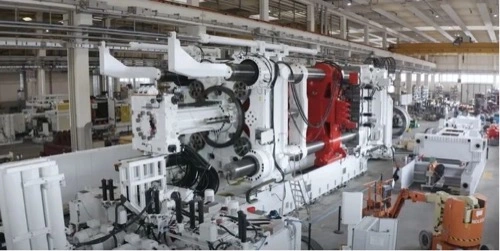

To make such a huge piece of metal, a huge die-cast machine is required. Tesla cooperated with the Italian company Idra to create a giant machine called Giga Press, which was activated in 2020. With a motor of 132 kW, can generate up to 61,000 kilonewtons of downforce.

Now Tesla has obtained a new version of the Giga Press OL 9000 CS, which weighs more than 450 tons and has a downforce of 90,500 kilonewtons. It has been installed in the Tesla Texas plant. Its task is to create the body of the pure electric truck Cybertruck.

Cybertruck adopts an integrally formed metal frame without baking paint, which is called an exoskeleton body. According to the operation principle of Giga Press, metal blocks such as iron, aluminum, silicon and magnesium are sent into the furnace and melted at a high temperature of 850 degrees Celsius. Through processing multi-channel gas, silicon carbide and other materials, the liquid metal is poured into the mold, and after high-pressure forming, it is taken out by a robotic arm. X-rays and lasers are performed to complete the entire process.

At present, the die-cast time of the Model Y body only takes about 90 seconds, that is, the output of 40 to 45 pieces per hour. The Cybertruck body is larger, so the die-cast time may increase, but in an ideal state, Tesla’s Texas plant will be able to complete the production capacity of about 1,000 vehicles per day.

When Cybertruck was released at the end of 2019, Tesla said that to produce this car, new production technology will be needed. It seems that this huge die-cast machine is one of the important keys to this new technology, and the other key is a 4680 battery.

At present, two major battery manufacturers have begun trial production of 4680 batteries. With the new die-cast machine in place, the goal of mass production of Cybertruck in 2023 seems no longer so far away.

Tesla Cybertruck can be said to be one of the most recognizable vehicles in the world. To create this peculiar car body, Tesla officially activated the world's largest die-cast machine, which means that it is a step closer to the mass production of Cybertruck.

In the past few years, Tesla has used one-piece die-cast technology to build the Model Y body. From the initial later half of the body, it has now developed into an integrated front and rear half to replace the original 70 kinds of parts, greatly reducing production costs and time.

To make such a huge piece of metal, a huge die-cast machine is required. Tesla cooperated with the Italian company Idra to create a giant machine called Giga Press, which was activated in 2020. With a motor of 132 kW, can generate up to 61,000 kilonewtons of downforce.

Now Tesla has obtained a new version of the Giga Press OL 9000 CS, which weighs more than 450 tons and has a downforce of 90,500 kilonewtons. It has been installed in the Tesla Texas plant. Its task is to create the body of the pure electric truck Cybertruck.

Cybertruck adopts an integrally formed metal frame without baking paint, which is called an exoskeleton body. According to the operation principle of Giga Press, metal blocks such as iron, aluminum, silicon and magnesium are sent into the furnace and melted at a high temperature of 850 degrees Celsius. Through processing multi-channel gas, silicon carbide and other materials, the liquid metal is poured into the mold, and after high-pressure forming, it is taken out by a robotic arm. X-rays and lasers are performed to complete the entire process.

At present, the die-cast time of the Model Y body only takes about 90 seconds, that is, the output of 40 to 45 pieces per hour. The Cybertruck body is larger, so the die-cast time may increase, but in an ideal state, Tesla’s Texas plant will be able to complete the production capacity of about 1,000 vehicles per day.

When Cybertruck was released at the end of 2019, Tesla said that to produce this car, new production technology will be needed. It seems that this huge die-cast machine is one of the important keys to this new technology, and the other key is a 4680 battery.

At present, two major battery manufacturers have begun trial production of 4680 batteries. With the new die-cast machine in place, the goal of mass production of Cybertruck in 2023 seems no longer so far away.