Blackening of Aluminum Alloy Die Casting after Impregnation

Abstract: Aiming at the problem of blackening of parts after impregnation of Shells of 6D product 15641015-1-Y, systematic analysis and discussion were carried out, and solutions were proposed to provide a solid theoretical and practical basis for the implementation of new processes in enterprises.

The development of automobile lightweight has promoted the rapid development of the material industry, followed by the transformation of the automobile transmission housing made from gray cast iron to aluminum alloy. The emergence of new materials has brought new technological changes, which is both an opportunity and a challenge for machining. To reduce the scrap rate of transmission casings caused by defects of aluminum alloy casting and the service cost of OEMs, the impregnation process has been widely used in the aluminum alloy casing process of enterprises and has achieved good results. The impregnation process emerged and developed simultaneously with new materials, and some problems also appeared in the process of using the new process.

Analysis of the problem

1. Equipment and problems

The independent production line of impregnation machines consists of six cylinders such as pre-washing cylinders, vacuum drying cylinders, impregnation cylinders, recovery cylinders, water washing cylinders and curing cylinders, as well as related control units and water pipelines.

1) The water washing of the parts is performed at 60 to 61°C and grease and dirt are removed in the pre-wash tank.

2) The vacuum drying cylinder performs vacuum drying after the parts are washed, and at the same time avoids the parts from being oxidized.

3) The impregnation cylinder completes the formal impregnation process of the parts, and seals micro-pores such as blow holes.

4) The recovery cylinder completes the recovery of excess impregnation liquid, aiming at reuse.

5) The water washing tank is used to rinse the impregnated parts, thereby improving the surface quality of the parts.

6) The curing cylinder is used to solidify the impregnating liquid at 93 to 94°C to stabilize the impregnating liquid.

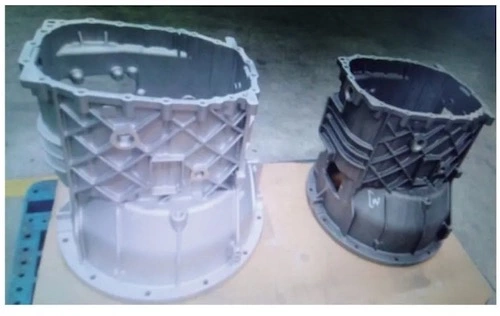

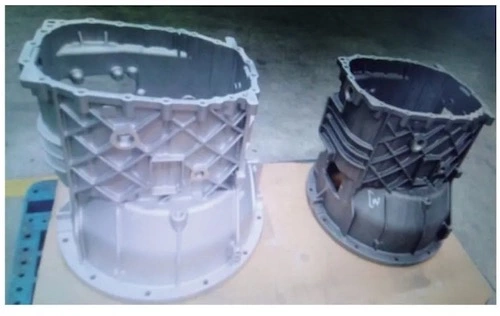

In each cylinder, the parts are kept for 10 minutes. When the impregnation machine is officially in circulation, one part can be impregnated in 10 minutes. The impregnating machine is the key equipment of the product (Figure 1). Since the airtight machine has not been officially handed over to this workshop, all S-class transmissions C6J40T, C6J50T and C6J70T shells are impregnated in the process to replace the airtight process, complete the quality inspection of the shell and have achieved good application results.

Figure 1 Impregnation machines

Prepare the solvents for each tank according to the operation instructions, including 2% of anti-oxidant (aluminum) in the pre-washing tank and 4% antioxidant (aluminum) in the curing tank. At the same time, adjust the temperature of each tank. The temperature is 93 to 94°C. Recently, after the impregnation of the 15641015-1-Y shell in C6J50T for Shell II 6D, it was found that the parts were blackened, and the blackening became more and more serious with the increase in the number of impregnations.

Through the tracking and observation of the blackening of the problematic parts. After the impregnation line is fully operational, there is no obvious difference in the color of the first 3 to 4 parts before and after impregnation. Starting from the fifth piece, the parts gradually turned black after impregnation, and the degree of blackening became more and more serious with the increase in the number of impregnated parts. Add 2% antioxidant (aluminum) to the curing cylinder again, and the color of the first three or four parts has no obvious difference before and after impregnation, and from the fifth part onwards, the color of the parts turns black again; this situation occurs repeatedly. By searching one by one, regardless of whether there is a supplementary antioxidant (aluminum), there is no blackening of the parts from the fifth cylinder. As shown in Figure 3, the blackening appears after the end of the final curing cylinder.

Figure 2 Before and after Impregnation

2. Analyzing the problem

After operating according to the operation instructions, there are problems. The reasoning is as follows:

1) The parts turn black after the curing cylinder treatment, which can fully explain that there is a problem in the curing cylinder process.

2) After each addition of antioxidant (aluminum), there is no significant difference in color before and after the impregnation of the first three or four products. The problem is the attenuation of antioxidant performance.

3) Since the material of the die casting is ADC12, which is an Al-Si-Cu alloy; aluminum or copper may be oxidized in the impregnation process.

4) Whether the effective working temperature of the antioxidant (aluminum) is too low, and whether it has failed at 93 to 94°C.

5) Whether the temperature display of the curing cylinder of the impregnation machine is consistent with the actual temperature.

6) Whether the concentration of antioxidant (aluminum) is qualified.

3. Solution

The following solutions are provided based on the results of the analysis in the above six aspects:

1) Use a concentration tester to detect the concentration of antioxidant (aluminum) in the curing cylinder aqueous solution. The test result shows that the concentration of antioxidants is greater than and equal to 4%, and the concentration of aluminum is within the normal range.

2) Use a water thermometer to detect the temperature of the aqueous solution in the curing cylinder, and the test result is 93°C. The actual detected temperature is consistent with the temperature displayed on the control cabinet, and there is no problem with the aqueous solution temperature.

3) After adding an antioxidant (copper), there is no difference between impregnated parts and no antioxidant (copper), and it is determined that copper is not oxidized.

4) Replace the antioxidant (aluminum) with a higher effective working temperature (96°C), and adjust the concentration of the aqueous solution in the curing cylinder to 4%; the problem is solved. After a week of follow-up, the production went on smoothly. After the problem was solved, the parts were shown in Figure 4, and the problem did not appear again. Subsequently, the Industrial Technology Research Institute, Shell No. 2 Workshop and the antioxidant (aluminum) manufacturer negotiated and decided that all antioxidants (aluminum) would be replaced free of charge by the manufacturer.

The development of automobile lightweight has promoted the rapid development of the material industry, followed by the transformation of the automobile transmission housing made from gray cast iron to aluminum alloy. The emergence of new materials has brought new technological changes, which is both an opportunity and a challenge for machining. To reduce the scrap rate of transmission casings caused by defects of aluminum alloy casting and the service cost of OEMs, the impregnation process has been widely used in the aluminum alloy casing process of enterprises and has achieved good results. The impregnation process emerged and developed simultaneously with new materials, and some problems also appeared in the process of using the new process.

Analysis of the problem

1. Equipment and problems

The independent production line of impregnation machines consists of six cylinders such as pre-washing cylinders, vacuum drying cylinders, impregnation cylinders, recovery cylinders, water washing cylinders and curing cylinders, as well as related control units and water pipelines.

1) The water washing of the parts is performed at 60 to 61°C and grease and dirt are removed in the pre-wash tank.

2) The vacuum drying cylinder performs vacuum drying after the parts are washed, and at the same time avoids the parts from being oxidized.

3) The impregnation cylinder completes the formal impregnation process of the parts, and seals micro-pores such as blow holes.

4) The recovery cylinder completes the recovery of excess impregnation liquid, aiming at reuse.

5) The water washing tank is used to rinse the impregnated parts, thereby improving the surface quality of the parts.

6) The curing cylinder is used to solidify the impregnating liquid at 93 to 94°C to stabilize the impregnating liquid.

In each cylinder, the parts are kept for 10 minutes. When the impregnation machine is officially in circulation, one part can be impregnated in 10 minutes. The impregnating machine is the key equipment of the product (Figure 1). Since the airtight machine has not been officially handed over to this workshop, all S-class transmissions C6J40T, C6J50T and C6J70T shells are impregnated in the process to replace the airtight process, complete the quality inspection of the shell and have achieved good application results.

Figure 1 Impregnation machines

Prepare the solvents for each tank according to the operation instructions, including 2% of anti-oxidant (aluminum) in the pre-washing tank and 4% antioxidant (aluminum) in the curing tank. At the same time, adjust the temperature of each tank. The temperature is 93 to 94°C. Recently, after the impregnation of the 15641015-1-Y shell in C6J50T for Shell II 6D, it was found that the parts were blackened, and the blackening became more and more serious with the increase in the number of impregnations.

Through the tracking and observation of the blackening of the problematic parts. After the impregnation line is fully operational, there is no obvious difference in the color of the first 3 to 4 parts before and after impregnation. Starting from the fifth piece, the parts gradually turned black after impregnation, and the degree of blackening became more and more serious with the increase in the number of impregnated parts. Add 2% antioxidant (aluminum) to the curing cylinder again, and the color of the first three or four parts has no obvious difference before and after impregnation, and from the fifth part onwards, the color of the parts turns black again; this situation occurs repeatedly. By searching one by one, regardless of whether there is a supplementary antioxidant (aluminum), there is no blackening of the parts from the fifth cylinder. As shown in Figure 3, the blackening appears after the end of the final curing cylinder.

Figure 2 Before and after Impregnation

2. Analyzing the problem

After operating according to the operation instructions, there are problems. The reasoning is as follows:

1) The parts turn black after the curing cylinder treatment, which can fully explain that there is a problem in the curing cylinder process.

2) After each addition of antioxidant (aluminum), there is no significant difference in color before and after the impregnation of the first three or four products. The problem is the attenuation of antioxidant performance.

3) Since the material of the die casting is ADC12, which is an Al-Si-Cu alloy; aluminum or copper may be oxidized in the impregnation process.

4) Whether the effective working temperature of the antioxidant (aluminum) is too low, and whether it has failed at 93 to 94°C.

5) Whether the temperature display of the curing cylinder of the impregnation machine is consistent with the actual temperature.

6) Whether the concentration of antioxidant (aluminum) is qualified.

3. Solution

The following solutions are provided based on the results of the analysis in the above six aspects:

1) Use a concentration tester to detect the concentration of antioxidant (aluminum) in the curing cylinder aqueous solution. The test result shows that the concentration of antioxidants is greater than and equal to 4%, and the concentration of aluminum is within the normal range.

2) Use a water thermometer to detect the temperature of the aqueous solution in the curing cylinder, and the test result is 93°C. The actual detected temperature is consistent with the temperature displayed on the control cabinet, and there is no problem with the aqueous solution temperature.

3) After adding an antioxidant (copper), there is no difference between impregnated parts and no antioxidant (copper), and it is determined that copper is not oxidized.

4) Replace the antioxidant (aluminum) with a higher effective working temperature (96°C), and adjust the concentration of the aqueous solution in the curing cylinder to 4%; the problem is solved. After a week of follow-up, the production went on smoothly. After the problem was solved, the parts were shown in Figure 4, and the problem did not appear again. Subsequently, the Industrial Technology Research Institute, Shell No. 2 Workshop and the antioxidant (aluminum) manufacturer negotiated and decided that all antioxidants (aluminum) would be replaced free of charge by the manufacturer.