Applications and Cost Control of 3D Printing in the Automobile Manufacturing (Part Two)

3.2 Applications of 3D printing technology to the automobile repair

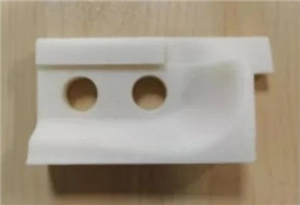

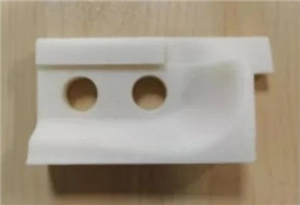

When a car is repaired, replacing parts is the most commonly used repair method. However, there are many models on the market, and 4S stores cannot be equipped with all the parts. It is easy to cause a shortage of parts and affect the maintenance schedule, which greatly affects the customer's maintenance experience. For some old models that have not been manufactured for many years, auto companies do not keep a stock of the part. If a single part is made separately, it will cause a waste of resources that the company is not willing to bear. At this time, the advantages of 3D printing technology in automobile maintenance are reflected. As long as the processing data of the parts and the three-dimensional digital model files are saved, the finished products can be quickly produced, achieving the goal of reducing manufacturing costs, bringing a better maintenance experience for customers and saving logistics costs, as shown in Figure 2.

Figure 2 3D printed repair parts

At the same time, different models need different maintenance tools in the car maintenance process due to the personalized design of the car. Some standard maintenance tools can only be provided on the market, which cannot meet some special needs. At this time, 3D printing technology is needed to produce some special maintenance tools. Generally, the internal space data of the car is obtained through a three-dimensional scanner, and the tool design is carried out based on the data. Finally, a 3D printer is used to quickly produce maintenance tools to improve maintenance efficiency.

4. Applications of 3D printing technology to the field of automobile assembly

4.1 Application prospects

The main advantage of 3D printing lies in its customizability, which can generate parts of any shape from computer graphics data, thereby greatly shortening the product's development cycle, improving production efficiency and reducing production costs. As an important process of automobile production, final assembly guards the bottom line of quality of automobile production. There are many complicated processes, and various assembly tools are also used in the assembly process. According to the process requirements of the assembly shop, assembly tools are divided into four categories: positioning tools, auxiliary tools, anti-scratch tools, and inspection tools. Different types of tools have different requirements for properties of materials. Although there are many kinds tools, the demand is small; the production cost is high, and the production cycle is long. If 3D printing technology is used, it can greatly shorten the production cycle of tools and indirectly improve the efficiency of automobile assembly. At the same time, the accuracy of the assembly tools is improved, and the assembly tools are standardized. If you need to make similar tools, you can make them quickly and easily by adjusting the parameters. During process exchanges with assemblers on different production lines of vehicle models, new assembly methods and assembly tools can also be better promoted, which is conducive to the improvement of the assembler's business ability.

4.2 Applications of 3D printing technology to dedicated assembly tools

The positioning tool is a special tool used to solve the X/Y/Z direction coordination between auto parts, parts and bodies, so that the assembly deviation is set within the standard range and meets the requirements of process and quality standards. There are positioning tools such as front and rear windshield positioning tools, front and rear windscreen wiper positioning tools, fender positioning tools, etc, as shown in Figure 3.

Figure 3 3D printed positioning tools

Auxiliary tools refer to tools used for auxiliary operations, making the process simpler and more convenient. It is mainly reflected in the improvement of ergonomics, assembly efficiency, and the satisfaction of quality requirements. There are auxiliary tools such as rubbing pen cover auxiliary tools, installation auxiliary tools for front wall sound insulation pads, tail door lock anti-closing auxiliary tools, etc., as shown in Figure 4.

Figure 4 3D printed auxiliary tools

The anti-scratch tool is an active protection control tool used to protect the paint surface of the car body, protect the surface paint of the car body from being scratched by sharp objects during the assembly operation, and eliminate the waste of paint repair. There are anti-scratch tools such as anti-scratch tools for door locks, anti-scratch tools for door locks, and anti-scratch tools for engine laser codes (as shown in Figure 5).

Figure 5 3D printed anti-scratch tools

An inspection tool is a tool used to measure the dimensional deviation between parts after assembly, and it is a special tool for designing and measuring the process parameter identification of parts. There are inspection tools such as installation and inspection tools for bright strips of car doors, storage battery and intermediate shaft measurement (as shown in Figure 6).

Figure 6 3D printed inspection tools

4.3 Cost control

Compared with the traditional tool concerning production methods and cycles, the application of 3D printing technology is conducive to improving quality and reducing tool costs. The best practice is that a total of 57 kinds (159 pieces) of special tools were developed using 3D printing technology, and a total of 70,000RMB was saved, providing advantages for high-quality and low-cost product output.

5. Summary

As one of the symbolic products of the third industrial revolution, 3D printing technology has been recognized by the majority of automobile companies, playing an important role in the field of R&D and maintenance, and effectively solving many practical problems. At the same time, with the development of material science, 3D printing technology will be more comprehensively used in the automotive industry, and will gradually be applied to the four major processes of automotive production, replacing some of the traditional manufacturing methods, thereby reducing input costs and proving assistance for the development of the automotive industry.

When a car is repaired, replacing parts is the most commonly used repair method. However, there are many models on the market, and 4S stores cannot be equipped with all the parts. It is easy to cause a shortage of parts and affect the maintenance schedule, which greatly affects the customer's maintenance experience. For some old models that have not been manufactured for many years, auto companies do not keep a stock of the part. If a single part is made separately, it will cause a waste of resources that the company is not willing to bear. At this time, the advantages of 3D printing technology in automobile maintenance are reflected. As long as the processing data of the parts and the three-dimensional digital model files are saved, the finished products can be quickly produced, achieving the goal of reducing manufacturing costs, bringing a better maintenance experience for customers and saving logistics costs, as shown in Figure 2.

Figure 2 3D printed repair parts

At the same time, different models need different maintenance tools in the car maintenance process due to the personalized design of the car. Some standard maintenance tools can only be provided on the market, which cannot meet some special needs. At this time, 3D printing technology is needed to produce some special maintenance tools. Generally, the internal space data of the car is obtained through a three-dimensional scanner, and the tool design is carried out based on the data. Finally, a 3D printer is used to quickly produce maintenance tools to improve maintenance efficiency.

4. Applications of 3D printing technology to the field of automobile assembly

4.1 Application prospects

The main advantage of 3D printing lies in its customizability, which can generate parts of any shape from computer graphics data, thereby greatly shortening the product's development cycle, improving production efficiency and reducing production costs. As an important process of automobile production, final assembly guards the bottom line of quality of automobile production. There are many complicated processes, and various assembly tools are also used in the assembly process. According to the process requirements of the assembly shop, assembly tools are divided into four categories: positioning tools, auxiliary tools, anti-scratch tools, and inspection tools. Different types of tools have different requirements for properties of materials. Although there are many kinds tools, the demand is small; the production cost is high, and the production cycle is long. If 3D printing technology is used, it can greatly shorten the production cycle of tools and indirectly improve the efficiency of automobile assembly. At the same time, the accuracy of the assembly tools is improved, and the assembly tools are standardized. If you need to make similar tools, you can make them quickly and easily by adjusting the parameters. During process exchanges with assemblers on different production lines of vehicle models, new assembly methods and assembly tools can also be better promoted, which is conducive to the improvement of the assembler's business ability.

4.2 Applications of 3D printing technology to dedicated assembly tools

The positioning tool is a special tool used to solve the X/Y/Z direction coordination between auto parts, parts and bodies, so that the assembly deviation is set within the standard range and meets the requirements of process and quality standards. There are positioning tools such as front and rear windshield positioning tools, front and rear windscreen wiper positioning tools, fender positioning tools, etc, as shown in Figure 3.

Figure 3 3D printed positioning tools

Auxiliary tools refer to tools used for auxiliary operations, making the process simpler and more convenient. It is mainly reflected in the improvement of ergonomics, assembly efficiency, and the satisfaction of quality requirements. There are auxiliary tools such as rubbing pen cover auxiliary tools, installation auxiliary tools for front wall sound insulation pads, tail door lock anti-closing auxiliary tools, etc., as shown in Figure 4.

Figure 4 3D printed auxiliary tools

The anti-scratch tool is an active protection control tool used to protect the paint surface of the car body, protect the surface paint of the car body from being scratched by sharp objects during the assembly operation, and eliminate the waste of paint repair. There are anti-scratch tools such as anti-scratch tools for door locks, anti-scratch tools for door locks, and anti-scratch tools for engine laser codes (as shown in Figure 5).

Figure 5 3D printed anti-scratch tools

An inspection tool is a tool used to measure the dimensional deviation between parts after assembly, and it is a special tool for designing and measuring the process parameter identification of parts. There are inspection tools such as installation and inspection tools for bright strips of car doors, storage battery and intermediate shaft measurement (as shown in Figure 6).

Figure 6 3D printed inspection tools

4.3 Cost control

Compared with the traditional tool concerning production methods and cycles, the application of 3D printing technology is conducive to improving quality and reducing tool costs. The best practice is that a total of 57 kinds (159 pieces) of special tools were developed using 3D printing technology, and a total of 70,000RMB was saved, providing advantages for high-quality and low-cost product output.

5. Summary

As one of the symbolic products of the third industrial revolution, 3D printing technology has been recognized by the majority of automobile companies, playing an important role in the field of R&D and maintenance, and effectively solving many practical problems. At the same time, with the development of material science, 3D printing technology will be more comprehensively used in the automotive industry, and will gradually be applied to the four major processes of automotive production, replacing some of the traditional manufacturing methods, thereby reducing input costs and proving assistance for the development of the automotive industry.